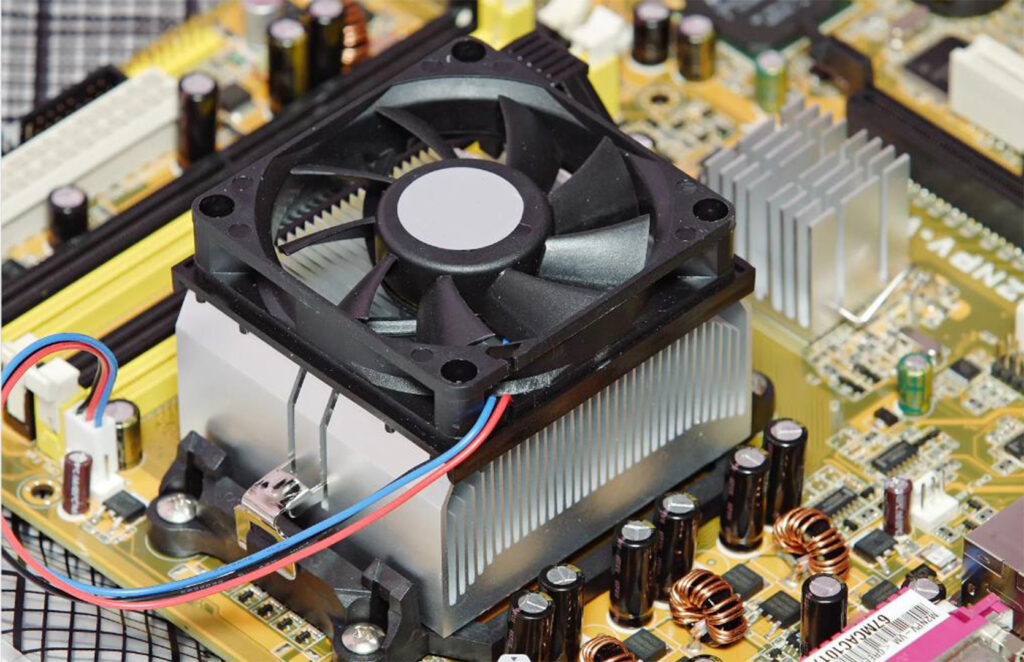

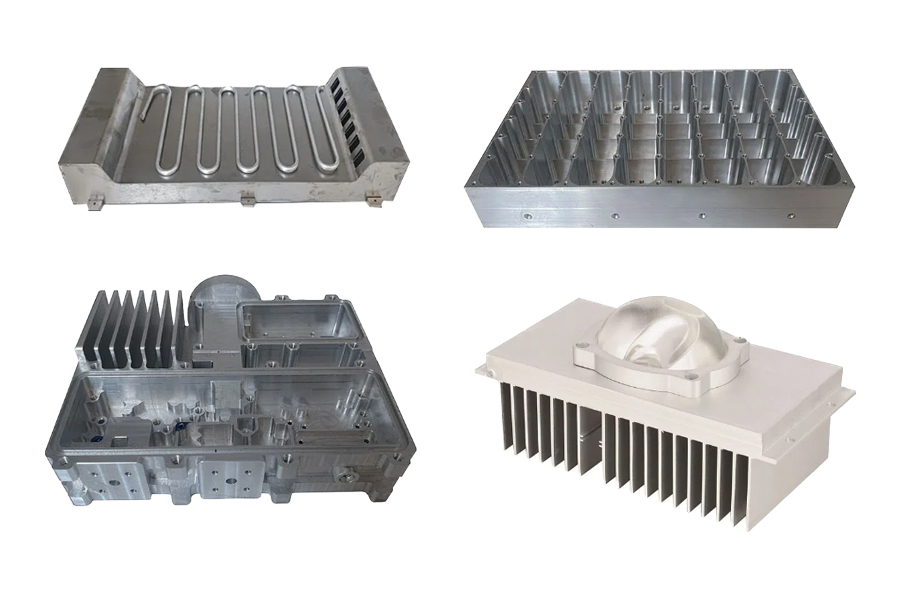

Electronic Component Heatsinks

Given that working life is under threat as electronic appliances generate heat at any time, it is important to install aluminum heatsinks for your electronic components.

Now, our various kinds of aluminum heatsinks are available for your choice. Especially the customized heatsinks can be produced according to your requirement.

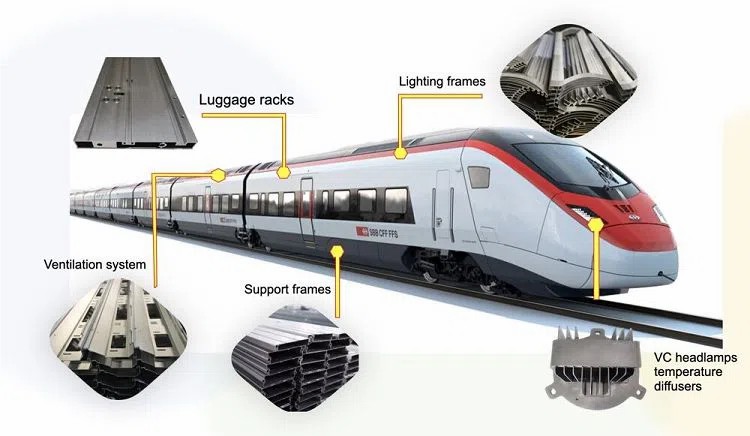

High Speed Rail Accessories

In 2016, we started to provide aluminum products and CNC patrs of the high speed train for CRRC. Our metro line and high speed train projects include Hongkong,Malaysia, Beijing, Changsha, Guiyang, Hefei, Urumqi, Korea, Serbia, Chinago, etc

New Energy Vehicle Parts

With the rapid development of the new energy vehicle industry, light weight, longer battery lifetimes have become the pursuit for new energy vehicle companies and composite materials are ideal for lightweighting.

The application of aluminum alloy parts in new energy vehicles is a key to achieving automobile lightweight.

At present, new energy auto parts we provide for our customers are: Battery tray, motor housing, aluminum guard bar, inverter heat sink, luggage rack and battery end plate, etc

Aluminum Parts for 5G Signal Tower

With a committment of putting high quality standard first, we provide customized aluminum profiles for the 5G signal tower.

Since 2018, we had been involving in this amazing 5G communication industry, and keep supplying over 10 different types of aluminum products to the customer.

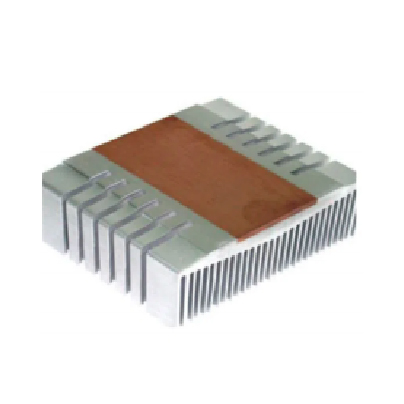

Vapour Chamber Heatsink

In 2015, Kaixin and Feicheng came together to form an R&D joint venture that works closely with domestic research institutes and universities. This venture, focuses on the research, development and application of core technologies for heat dissipation and heat transfer.

Technologies such as composite phase change working fluid, multiple sintering material, multidimensional phase change heat transfer and separation phase change heat transfer, have several fields of application such as military industry, communication, IT, new energies and railway transit, and are some of the efficient and reliable heat dissipation and heat transfer solutions we offer.

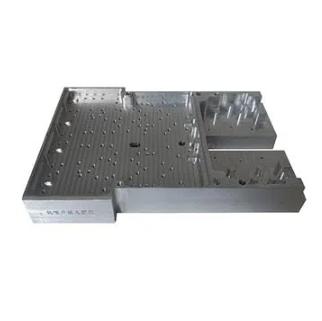

Aluminum Cabinet for Electrical System

Those cabinets are mainly used to encapsulate electrical systems including switching equipment, measuring instruments, and auxiliaries.

Total over 200 different aluminum parts, we assembly them together by welding and screwing, we have been working on this project for over 5 years, every year we have finished delivering around 500sets to different rails and bullet trains.

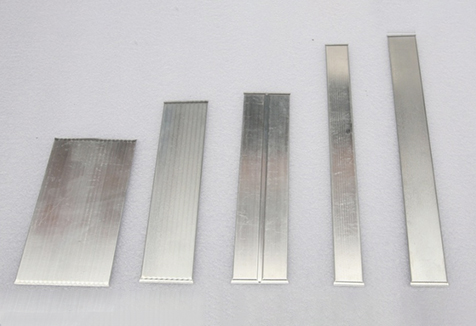

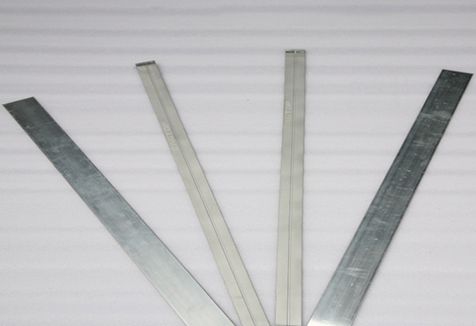

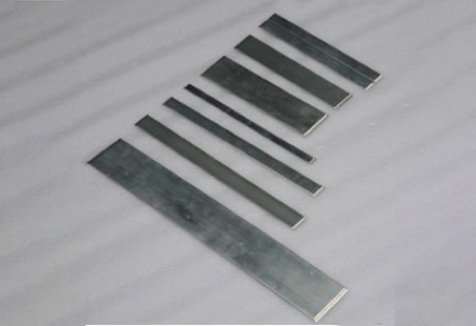

Superconducting composite flat heat pipe

Features:

Long-distance heat transfer and dissipation

Super heat transfer capacity per unit area

Excellent temperature control

Centralized heat treatment mode

No cooling power, energy efficient

High safety and reliability

Low processing cost

Applicable to notebook, Desktop, Server and other IT modules, can also be applied to LED TV backlight modules and 3C heat dissipation and heat transfer products such as LED lights and mobile phones.

Can be used as EV electric vehicle battery BMS to manage the use of uniform temperature and heat transfer elements

Thermal conductivity :

Kx>20000W/m.k

Ky>5000W/m.k

Kz>500W/m.k

Compressive strength :>2.0Mpa

Weight: 1/3 similar copper heat pipes

Cost:<1/3 similar copper heat pipes

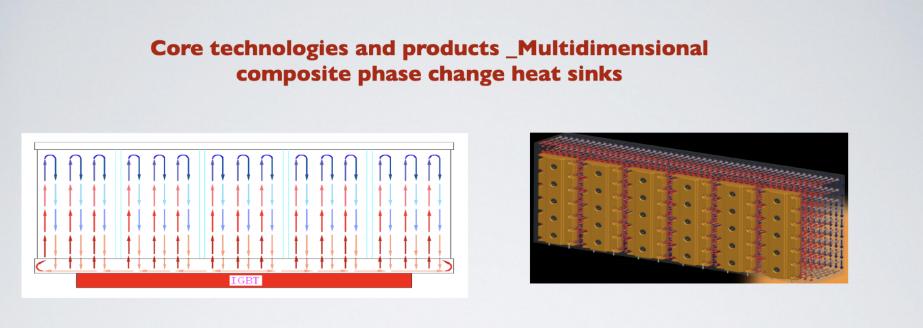

Multidimensional phase-change heat transfer heat sink with improved heat transfer capacity and heat exchange performance

Compared to the traditional structure of the uniform temperature plate and heat pipe.

1. Because of the phase change technology applied to the contact area (substrate), contact thermal resistance can be effectively controlled and reduced.

2. Given that the substrate and each fin form a multidimensional phase transition transfer channel, the thermal resistance from the heat source (substrate) to the fin is effectively reduced, and the heat exchange efficiency between fins is improved.

3. The multidimensional phase-change heat transfer heat sink has higher heat transfer performance and optimized volume structure

4. According to module requirements, the shape of any external variable substrate and the size of structural holes can be designed (meet the structural requirements that cannot be met by traditional stamping such as multi-hotspot complex system).

5. Better structural strength than heat transfer pipe counterparts and the uniform temperature plate.

6. The production technology of multidimensional phase change heat transfer heat sinks enhances the reliability of production and effectively guarantees the consistency of products.