Category

It is well known that heat sinks industry has seen rapid growth since the early 1900s, but custom heatsink manufacturing is a service that has only emerged in recent years. Though it has been emerging in a short period, customized processing is becoming one of the most popular services in emerging industries. Because of the unique design, size, and material of custom heat sink, it isn’t easy to find a custom heat sink design with the exact specifications on the market. This article will explore the intricacies of custom fabrication and explain how the process is formed. With this information, you will also learn about the advantages and disadvantages of traditional versus custom manufacturing.

What is customized manufacturing?

Custom manufacturing is the process to change raw materials into specific shapes for the application of different industries. It cannot be solved in a standard way but is designed according to customer demand. Distinguished from custom manufacturing, traditional manufacturing is a process that pre-produces the same products as the customer’s request. For example, cotton clothes manufactured during winter promotion.

Why choose customized manufacturing?

+ Inventory reduction: Customers want to deliver a large number of custom heat sinks in a short term. Anyway, custom machining can let that happen.

+ Specific needs: Customers may want a heat sink with certain characteristics that are not always met by traditional manufacturing methods, so custom manufacturing becomes necessary.

+ Consistent performance: The customer expects the custom heat sink has outstanding thermal performance, which means manufacturing processes and materials both are optimal.

+ Improved safety: For some special applications, such as engineering equipment or military facilities with a complex structure. Mass-produced heat sinks do not exactly meet their demands.

What factors led to the emergence of customized processing?

Sophisticated Modern Equipment

With the development of new technologies, modern equipment is becoming more and more sophisticated, leading to progressively higher requirements for thermal conductivity or thermal resistance of custom heat sinks, which means manufacturers need to constantly improve their custom heatsink design to meet different customer requirements, such as the number of fins, shapes, the thermal interface properties, etc… Therefore, the custom processing has become necessary.

Industry 4.0

Industry 4.0 is a concept about converging sensors, software, and the Internet of Things. Thanks to cloud-based technology, companies are moving to a new model where traditional in-house teams can now collaborate virtually, making it easier to create and implement more custom heat sinks.

Digital Manufacturing

Heat sink manufacturers can identify and eliminate bottlenecks and potential issues by leveraging digital manufacturing processes. They can design new custom heat sink by using 3D scanning and 3D printing technology. In addition, the digital industry bridges the gap between customers and manufacturers, making it easier for customers to access information about heat sink manufacturing in real time to maximize mutual cooperation.

How to implement custom heat sinks manufacturing

In custom heat sink manufacturing, the customer submits production CAD drawings to the manufacturer, who evaluates your custom heatsink proposal and sends you a quote. Once payment is made, the manufacturer starts manufacturing in about 7-15 days. Once production is complete, the manufacturer will QC custom heat sinks several times to ensure a pass rate of 99% or higher. Finally, the finished custom heatsink is sent directly to your specified address.

Although this customized processing is an ideal manufacturing way for small and medium-sized enterprises. But the fact is that even large companies like Amazon and Alibaba use this manufacturing business.

Advantages and disadvantages of traditional versus customized manufacturing

Traditional Manufacturing

Generally, manufacturers start manufacturing after receiving order. Once production is done, custom heat sinks are shipped to a warehouse for storage. This processing allows for a significant reduction in cost due to the fact that high-volume production reduces the additional costs of custom tooling, fixtures, etc.

Advantages

l Uniform Specifications: the finished heat sink with same specifications is guaranteed

l Low Unit Cost: high volume production means that costs are significantly reduced and there is no need to customize multiple molds.

Disadvantages

l High Initial Cost: Buyers need to produce large quantities to spread the cost of each heat sink. And high-volume production represents higher prices.

l Long Lead Time: The buyer needs to find a manufacturer, ask for a quote, etc. before placing an order. Manufacturer has to verify the purchaser’s qualifications before manufacturing, which approximately takes several weeks.

l Backlogged Inventory: With shrinking customer demand and squeezing inventory, several risks must be considered.

Customized Manufacturing

Custom fabrication is designed to meet the needs of different consumers. Custom fabrication offers several unique advantages as it avoids backlogs of inventory and provides solutions for customizing heat sink as well.

Advantages

l Simplify Operations: Customers outsource production to manufacturers, which simplifies their own company operations and allows them to focus on what they do best

l Personalization: Customers can choose the most appropriate manufacturing process for their needs, instead of having to choose an off-the-shelf mold for traditional processing.

l Flexibility: Customers can update their designs at any time and produce new heat sinks as needed in a very short period of time.

l Storage Costs: After manufacturing, manufacturer is able to deliver the radiator directly to the customer.

l Sourcing: Manufacturers have long-term strategic partners, meaning they receive lower material costs when customers engage manufacturers to source aluminum alloys.

l MOQ: No minimum order requirement. Customers are able to choose the quantity according to their demands.

l Quality Control: Due to the small production volume, the manufacturer is able to strictly control the quality of each heat sink to be able to achieve more than 99%.

Disadvantages

l Few Custom Services: Some manufacturers do not have a wide range of custom businesses due to their qualifications, capital, or technology. They can only provide some basic custom processing business. As the heat sinks are sophisticated, the manufacturer cannot provide you with a custom heatsink design. Therefore, make sure that the manufacturer has the following qualification before making a payment: ISO 9001 (international quality standard), ISO 14001 (environmentally friendly standard), IATF 16949 (qualification of automotive parts manufacturing ), EN 15085 (qualification of train parts manufacturing ), etc.

l Intellectual Property Plagiarism: Some untrustworthy manufacturers will sell your CAD drawings to other companies. Therefore, it is important to choose a heat sinks manufacturer with good customer credit.

l Insufficient Production Capacity: Although the manufacturer was able to provide high quality heat sinks in small volumes, it performed poorly in mass production when customers increased. Therefore, conventional processing proved to be a better option to save production costs and increase the feasibility of high-volume manufacturing.

What custom heatsink processes are available?

There are many techniques for manufacturing custom heat sinks, including:

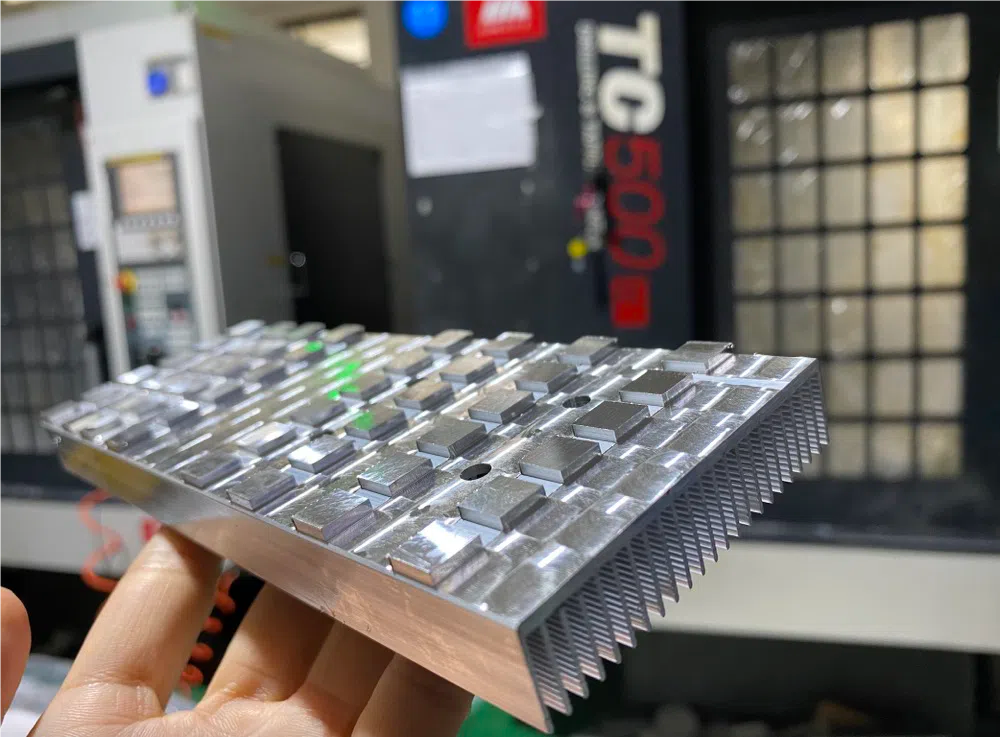

CNC Machined Custom Heat Sink

Machined custom heat sinks are made with the highest precision through deep process CNC. In addition, you can choose from different custom heat sink materials such as aluminum or copper to achieve specific heat dissipation properties. Currently, there are different types of CNC machines and special cutting tools, each with its own purpose and design specifications.

Extruded Custom Heat Sink

The extrusion process is one of the most common custom heat sink designs. The advantage is that it can provide different thermal solutions by changing the surface area and the number of fins. In addition, extruded custom heat sinks provide significant heat distribution capacity with an affordable heatsink cost.

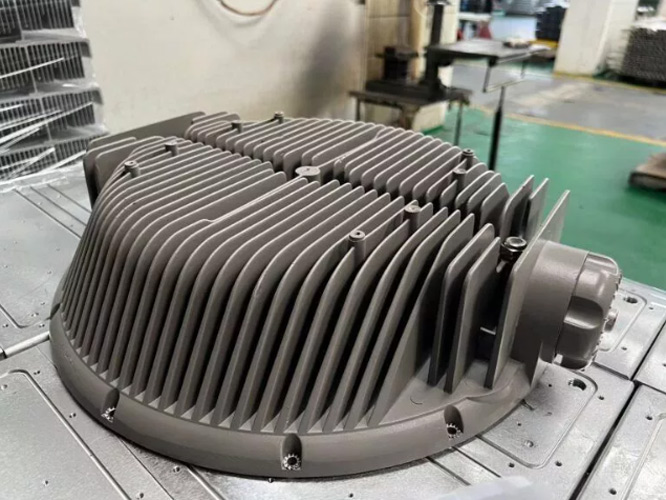

Die Casted Custom Heatsink

This customized heat sink is suitable for large mechanical equipment with complex features. Due to the high aspect ratios of the heat sink, it has high thermal conductivity and is capable of eliminating heat dramatically.

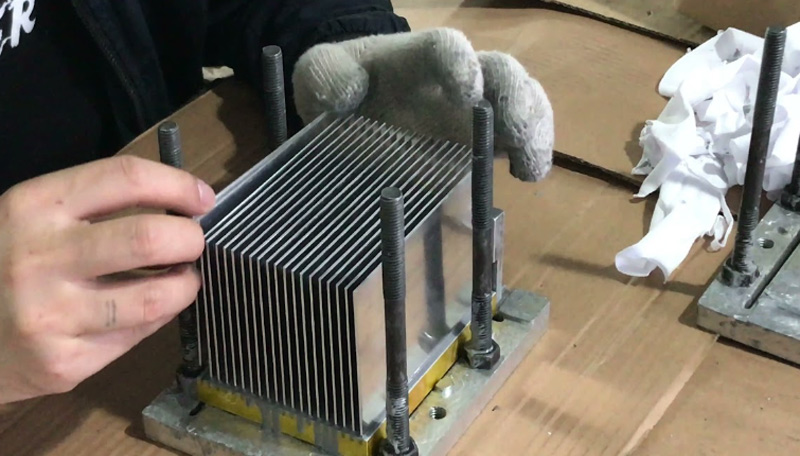

Skived Custom Heatsink

With the controlled shaving technique, you can change the number and thickness of fins to create heat sink with different thermal performance according to your needs.

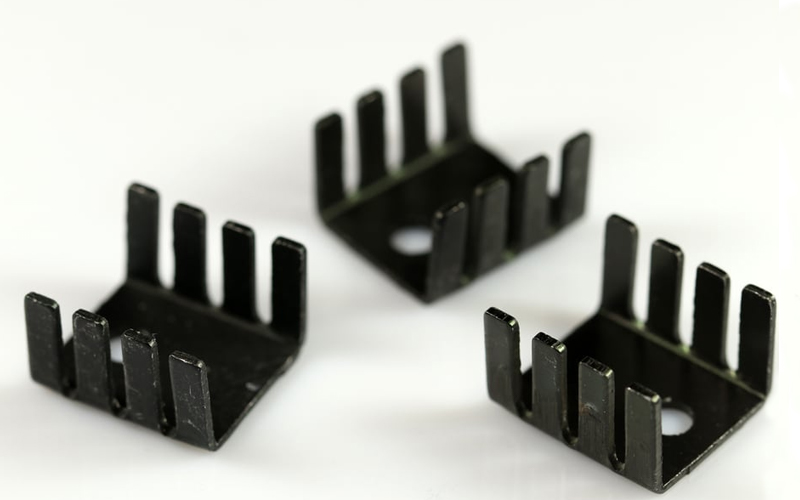

Cold Forging Custom Heat Sink

These custom heat sinks are mainly used for small mechanical and electronic devices. Due to their small size, these heatsinks are treated with a surface finishing such as silver plating or powder coating to increase their service life.

Metal Stamping Custom Heat Sink

Stamped custom heatsinks are one of the cost-effective custom heat sinks that are mainly used for cooling electronics. The stamping process provides an excellent method for producing lightweight heat sinks with high efficiency, high aspect ratio, and small package size, which is a good choice for medium-to-high volume production. This technology also offers a low Non-Recurring Engineering Charge (NEC).

Folded Fin Custom Heat Sink

Folded fin heat sinks have much thinner fins than extruded ones, so they are lighter in weight with better air flow, and low cost. Due to their special process that increases the number of fins and surface area, heat sinks are perfectly suited for high heat flux electronics.

Bonded Fin Custom Heat Sink

This custom designed heatsink is an assembly with a recessed base and individual fins bonded in the recess. Compared to the extrusion process, these custom heatsinks manufacturing allows for higher fin density and fin aspect ratio, which greatly improves thermal performance due to the increased surface area.

What are custom heat sinks currently used for?

Space Constrained Enclosures

Space constrained enclosures represent higher ambient temperature, so more efficient custom heat sinks are necessary. For example, custom heat sinks are the best choice for cooling small equipment such as automotive electrical components, welding machines, and RF amplifiers.

High Strength Applications

Mainly used in high-tech sectors such as military, aerospace, where custom heatsinks gift high tensile strength and yield strength to resist external impact, so it is recommended to choose 70 series aluminum materials such as 7075. In addition, the target temperature should be controlled within a certain range to avoid burning out the equipment.

High Power Equipment

Since large machinery generates extensive heat source, custom heat sink with higher thermal conductivity owns better power handling capabilities, which reduce power consumption dramatically.