Surface Finishing

Surface treatment is to give a certain appearance or special properties to heatsinks by changing the color, material and texture of the finished product. Through this method, the corrosion resistance, electrical conductivity, hardness, etc. will be enhanced significantly. Most heatsinks will use surface treatment that increases their service life.

With 15-year experience in the aluminum industry, Kaixin Aluminum offers varied surface treatment services for heatsinks. We own a team of experts who specialize in the surface treatment are committed to providing professional and high-quality surface treatment services for your products. If you would like to learn more about services in Kaixin Aluminum, please contact us without hesitation.

What services you can get?

Anodize

Anodizing is the most popular surface treatment. Our heatsinks are anodized to improve their corrosion resistance.

Anodize services we currently offered

Type 1: Boric acid/sulfuric acid anodizing features the most common and lowest-cost process with a density of 0.08-0.25um.

Type 2: Sulfuric acid anodizing has a clearer color than type 1 with a density of 2.54-25um.

Type 3: Hard anodizing has excellent corrosion resistance with a transparent oxide layer with a density of 12.7-80um.

Powder Coating

Featuring a dry coating process, it can provide strong corrosion resistance and durability equivalent to the anodized components. Meanwhile, it can be processed with various colors such as black, bronze and red.

Electroplating

Electroplating is the process of depositing a thin layer of metal onto another metal or other material that can be used to change the electrical conductivity of a surface.

Plating services we currently offered:

1, Nickel Plating

2, Copper plating

3, Gold plating

4, Silver plating

5, Chrome Plating

Sand Blasting

Sandblasting is a process that utilizes high-pressure air to spray abrasive particles onto the heatsink surface. We can make sandblasting to products as you require to keep that aesthetic and well-decoration.

Sandblasting materials currently available:

- Fine Sand

- Grit

- Glass Sand

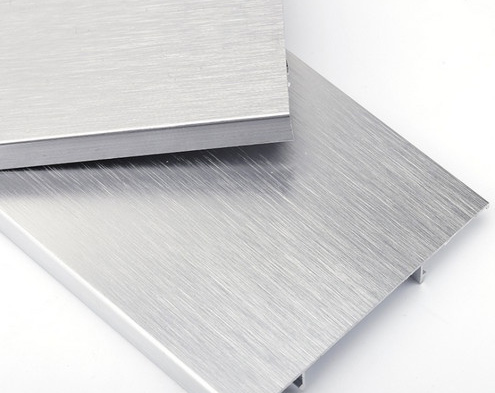

Hairline Finishing

Hariline is a process that aluminums alloys are forced through the die by an external force to obtain the required cross-sectional area, shape and size.

Polishing

Polishing is to provide a sound surface finish for your aluminum product with an aesthetcic appearance.

Wood Grain Aluminum

It is a crucial process for enhancing your furniture appearance that meets the high-end impression. Kaixin can color you aluminum allos with wodden, coffee, blue, etc.

Paint Spraying

Similar to powder coating, the painting process provides aluminum with a durable, aesthetically pleasing surface. With multiple times of spraying, this creates a uniform surface with even coverage that will not chip or fade over time

Passivation

Since metals corrode at ordinary temperatures, passivation changes the metal reactivity to reduce the rate of surface oxidation dramatically. Featuring economically simple manufacturing than anodizing. We also provide customized passivation as your demands.