Aluminum Heatsink Service

If you are looking for an aluminum heatsink manufacturer, there are some factors that you may concern about, such as the quality, MOQ, delivery time and the capabilities.

In Kaixin Aluminum, We have no high MOQ requirement but reasonable price and fast delivery. At the same time, we own many advance equipment which can provide you both time and cost-saving solution for your project.

Customization

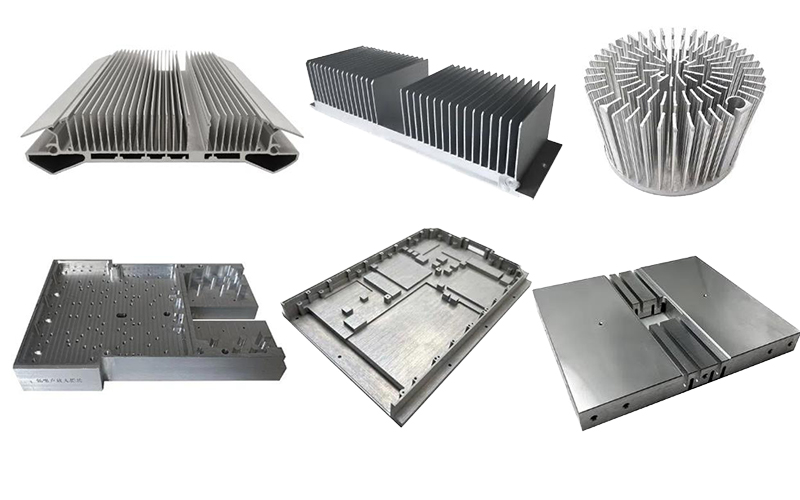

We provide various of customized aluminum heatsinks we not only provide you with the extrusion service but also CNC machining, including milling, drilling, turning and stamping.

Good Price

Well-equipped, high production efficiency and strong capability, Kaixin can give you the favorable price to meet your budge.

Fast Delivery

If you don't want to wait that long, then come to us. Every time you need the urgent order, we can deliver.

Custom Heat Sink Service

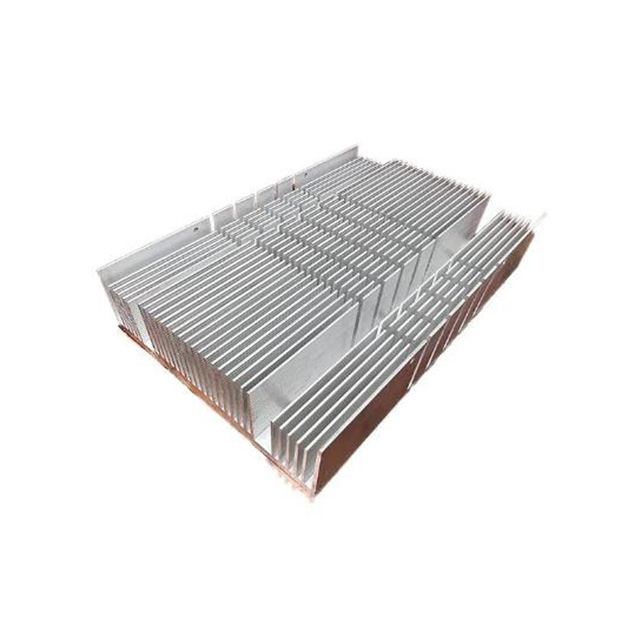

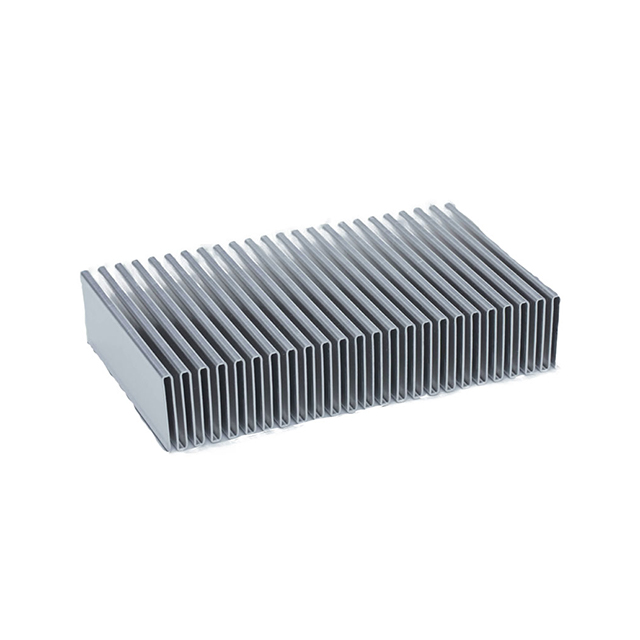

Aluminum Extrusion Heat Sink

With good corrosion resistance, we mainly use aluminum 6061, and 6063 to manufacture heatsinks.It is mainly used in high-power electronic parts and some of which use in LED light, lamps, etc.

Metal Stamping Heat Sink

With low cost and high production efficiency, our metal stamping heatsinks are

manufacturered by progressive tool with in a very precision tolerance.

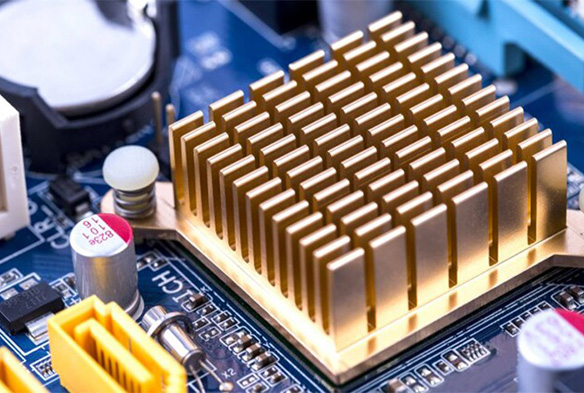

What is Aluminum Heatsinks?

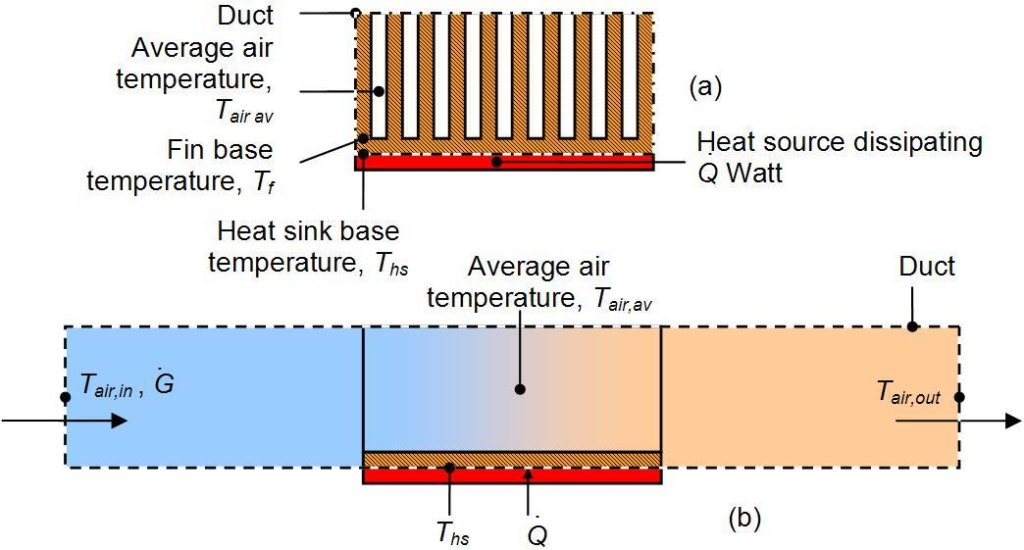

Heatsinks are most commonly used in heating and cooling systems to transfer heat from the hot fluid inside to the cold air outside, cooling the fluid inside, a process also known as convection.

By changing the size of the heatsink specifications, the manufacturing process makes it possible to install it on different equipment; At the same time the distribution and size of the heatsink blades determine the heatsink’s thermal performance.

How Does Aluminum Heatsinks Work?

There are two distinct types of convection:

Natural convection – Due to transfer of heat from the surface of a solid to the fluid particles in close proximity, the movement of the fluid particles is caused by the local changes in density.

Forced convection – the movement of the fluid particles is caused by an additional device such as a fan or blower.

Heat sinks work by redirecting heat flow away from a hot device. They do this by increasing the device’s surface area. In order for heat sinks to properly work, they must have a temperature higher than the surroundings to transfer heat.

Aluminum Heatsinks Applications

- Solar photovoltaic

- Aerospace

- Military Industry

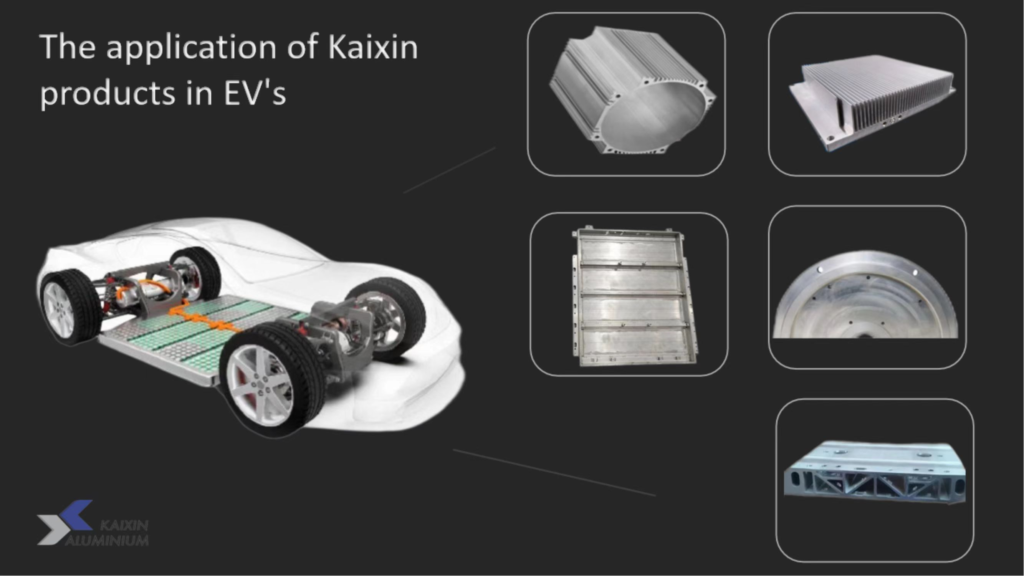

- Lightweighting Automobiles

- Infrastructure

- Electronics

- Medical

- Train

CNC Machining for Aluminum Heatsinks

It is a subtractive manufacturing process using computer-controlled machine tools to produce high-precision parts. The entire process requires control of tight tolerances, cutting times and material hardness. The CNC machining process is widely used in producing high-precision parts related to the aerospace, medical and automotive industries.

CNC Milling

CNC milling is a computer-controlled process that can be used to create very precise components. Boasting an accuracy that can reach an error of 0.01 mm, the advantage of using a CNC machine is that it can produce parts with a higher degree of precision than a human. In addition, CNC machines can be programmed to create very complex designs.

CNC Turning

CNC turning is a machining process that uses a computerized digital control (CNC) to rotate the workpiece while feeding the cutting tool into the workpiece. This allows for precise and repeatable machining of cylindrical parts. CNC turning can be used to produce parts with complex geometries, such as those with multiple tapers or contours.

CNC Drilling

A CNC drilling machine is a computer-controlled machine used to drill holes in a variety of materials. The machine is equipped with a drill head mounted on a spindle that moves in a linear or rotary motion. The speed and depth of the drill is controlled by the CNC machine.

Custom Aluminum Heatsinks

For custom aluminum heatsinks in non-standard shapes, Kaixin Aluminum is your best choice. This is because we can accept orders in different batches while allowing you to custom aluminum heatsinks

In addition to accepting orders in different batches, we can also provide surface treatment services including blasting, polishing, anodizing, etc. to ensure its durability. Besides, CNC machining is your best choice to customize heatsink to suit diferent machines.

Surface Treatment for Aluminum Heatsinks

To meet different demands for our customer , Kaixin Aluminum are committed to providing every surface treatments such as adding colors, engraving text, logos to the surface as you want for aluminum heatsinks with different applications.

Polishing

Finishing such as polishing, bead blasting and grinding can be performed. Polishing is one of the most important processes to maintain the aesthetic and comfortable touch. Meanwhile, it also a sign that prepares for other surface treatments.

Electroplating

To improve the appearance or function of a part, electroplating is often used in conjunction with other surface treatments, such as anodizing. We can coat aluminum heatsinks with a variety of metals, including gold, silver, nickel and copper to keep aesthetic and a good touch.

Powder Coating

Featuring a dry coating process, it can provide strong corrosion resistance and durability equivalent to the anodized components. Meanwhile, it can be processed with various colors such as black, bronze and red.

Painting

Whether aluminum heatsinks require a matte, glossy or textured surface, painting is an effective way to change its color and surface appearance.

Anodize

Mainly anodize Type II with the thicknesses of film between 0.0002 and 0.00040 inches (0.005-0.102 mm) for ensuring a scratch-resistant and adodizing-resistant coating with an excellent cosmetic appearance.

Applications of Aluminum Heatsinks

Aluminum heatsinks is widely used in heavy industry, aerospace, the medical and elsewhere. Common heatsinks we use include extrusion heatsinks for LED,CPU heatsinks,household heat sink, etc.

Construction

Common alluminum alloys include 6060, 6061, 6063, etc.,which are widly used in construction engineering such as aluminum frame or tube for enhancing building structure.

Electronic Components

Thanks to its thermal conductivity, aluminum are used in many crucial devices such as IPC, relay, inverter, charging port, etc.

Automobile

We obtianed IATF 16949 in automobile sector, providing us with a opportunity to manufacture aluminum parts such as DC converter, engine heat sink, traction battery pack, etc.

Aerospace

Heat sinks have also made their outstanding mark in aerospace. The most proportion of current civil aircraft uses them to manage the heat generated by avionics and propulsion systems. One of the most famous examples of heat sinks is the solid rocket boosters for the Space Shuttle.

Military

Thanks for obtaining military certificate. Vapour chamber, water cooling plate, heatsink for submarine all are manufactured by Kaixin in the wave of military advancement in latest year.

LED Lighting

As we know LED lightings feature various junction temperature affecting the working life of electronic components. Kaixin are pleasant to offer you with LED lighting heat sink ranging from 100W, 150W,300W, etc.

Check the various kinds of custom heatsink service we provide

Extensive Know-How in the field of aluminum heat sink, Kaixin’s goal is to help our customers lower production costs at high quality and high volumes. At the same time, we invested a lot on the development of the latest heat dissipation technology to meet the different thermal requirements.

Custom Aluminum Heatsink FAQ

Q: Why choose Kaixin Aluminum?

Thanks for the good customer feedback, we can provide aluminum heatsinks in different batches at competitive prices.

Q: Can I specify other aluminum alloy?

A:Mainly use 6063 and 6061. If you have requirements for materials, we will do our best to meet your demand.

Q: Is aluminum processing outsourced to other factories?

A:No, Kaixin Aluminum is dedicated to providing various processing services for aluminum heatsinks. Our original heatsinks are provided by our reliable partner and then we provide professional CNC machining and surface treatments as your required.

Q: How to guarantee the quality?

A:After processing, we will arrange for technical engineers to measure the specifications on the spot. Most importantly, we will randomly select the finished products for pressure testing to ensure that the qualification rate is over 95%.

Q: Can I get a sample for reference?

A: We will be happy to provide you with samples to ensure that the quality meets your standards. If you need it, please contact us!

Q: What are your payment terms?

A: We usually accept a 30% T/T payment in advance and the balance payment before shipment. Other payment terms are also negotiable.