Metal Stamping Manufacturing

Kaixin offer you one-stop customized metal stamping solutions for your choice. Our metal stamping services include bending, punching, cutting, dimpling, flanging, etc.

Our metal stamping parts are widely used in electronic components, automotive parts and medical devices.

Advantages of Sheet Metal Mnaufacturing

1, Material Selection

Aluminum + , copper, stainless steel + and iron.

2,OEM Available

Make your idea or drawings to reality.

3, Production Efficiency

High efficiency production capability to enhance competitiveness in the market

4, High Precision

get your precision products with our advanced equipments and outstanding mold’s design

5, Surface Treatment

Electroplating, anodizing, nickelplating, etc. are available.

6, Fast Delivery

Parts can be delivered in two weeks.

Common Metal Stamping Applications

- Household Electronic Appliances

- Fender

- Car Bonnet

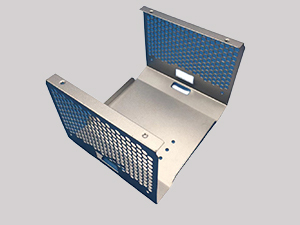

- Computer Casing

- Pan

- Baking Dish

- TV panels

- Office Equipment

- Fuselages

What is Metal Stamping Manufacturing?

Metal stamping is the process to manufacture components by punching, cutting, stretching and bending. The thickness of stamped sheet metal ranges from 0.25mm to 12mm, while the maximum width of less than 600mm. Due to the simple processing method, high precision and low cost, metal stamping products are popularised by customers at home and abroad.

Stamped parts can be used to assemble large machinery or end-use parts. But we should acknowledge that most end-use sheet metal parts generally require a CNC finishing before there are ready for market.

How to Get Your Metal Stamping Sheets

Upload CAD

Simply to provide us the CAD drawing and requirement.

Quotation and Design

You will receive our quote shortly after our engineer analysis

Order Confirmation

Once you review the quote and place the order, we will start the metal stamping manufacturing and surface treatment if needed be.

Fast delivery

After production, the final product will be 100% QC inspected and delivered to you.

Metal Stamping Materials We Offer

- Aluminum Alloy

- Copper alloy

- Carbon steel alloys

- Alloy Steel

- Iron

Metal Stamping FAQ

Q: Can I get a sample?

A: Yes, we will be happy to send you samples which will help you to understand our quality.

Q: Do I need laser cutting or water jet cutting?

A: All that depends on the material and sheet specifications you selected, as well as delivery time and processing tolerance.

Q: Does it cost more to use single tool comparing to the progressive tool

A: Generally speaking, the component that using single tool design will cost more than a part that using progressive tool.

Q: How long does the shipping time take?

A: Around 15-30 days

Q: Do you have a MOQ requirement?

A:We have a very low MOQ requirement. And the MOQ depends on your design.

Q: Why is the price different from one factory to another?

A: The design of the tool, the manufacturing technique and the quality control standard effects the difference of cost.

Q: What should I do if the product does not meet my requirements?

A: We will fulfill all requirements and take responsibility for all defects.