CNC Machining Services

Customize your CNC machining part in aluminum and metal

- High precision machining with 0.05mm

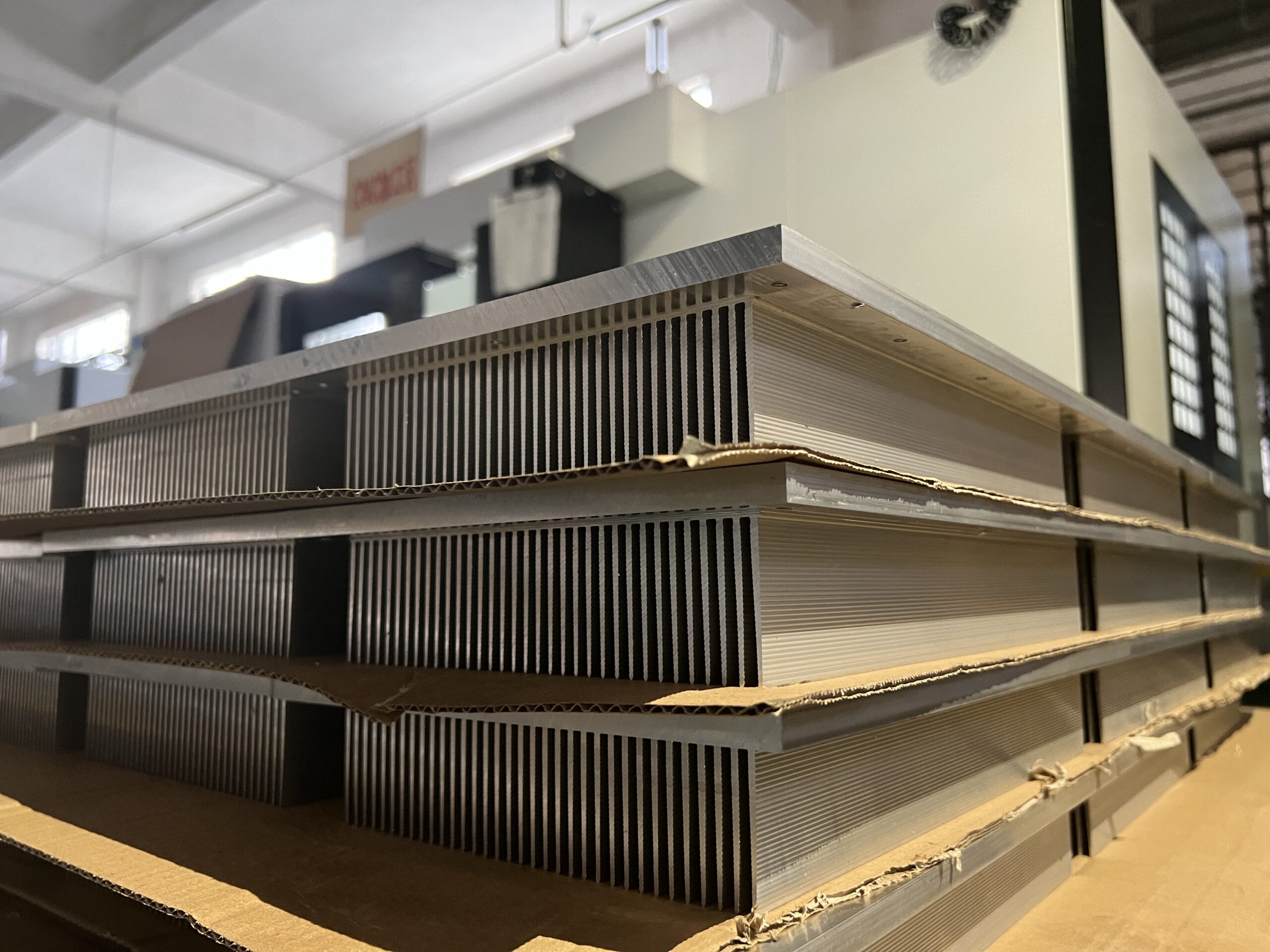

- Customization in different heat sinks

- Machining 600k+ per month

Kaixin Aluminum are commmitted to providing a wide range of CNC precision machining services, including milling, turning, drilling and surface anodizing. With 18 sets Machining centers, 2 sets PIA-6500 CNC, 3 sets 4 a-axis CNC Automatic precision combined with our 15-year experienced working terms and innovative capability, our CNC customized service will be the best choice for you. Contact us soon for getting more information about our CNC machining within 24 hours!

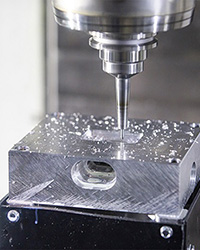

CNC Milling

CNC milling is a subtractive process that utilizes 4 axis nilling machining to manufacture precise components. using CNC milling is faster than human handcraft with a tolerance at 0.001mm.

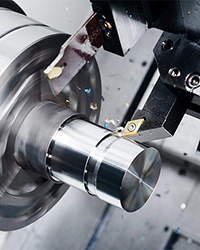

CNC Turning

CNC turning features a precise and repid way to manufacture round component, or some parts with complex geometry with multiple tapers and contours.

CNC Drilling

CNC drilling characterizes a effective way to drill holes with different depths and sizes in the product, featuring a sound way to customize product.

Experience

1,With over 15-year experience in aluminum industry

2,Own experienced research tearms and laboratories

3,Professional sele teams bringing you satisfactory pre-after sale services.

Strict Quality Control

1,Pay close attention to

every step during the production

2,measure every final products when is done

3,Randomly selected samples for pressure testing

Qualification

1, 6 invention patents and hold more than 30 utility models regarding to the aluminum heat sink industry

2,Being Titled as “High-Tech Enterprise” and “Member of High-Tech Industrial Association” in China.

3,Authoritative certification across the blobe, incluing ISO 14001,ISO9001, SGS, etc.

OEM Service

1,produce various kinds of aluminum heat sink from extrusion, machining to anodization.

2,manufacture your products with a custmized label

How do our customers rate us?

What should you consider when utilizing CNC Machining

If you’re considering CNC customization, it’s important to know what materials and finishes will meet your needs.

kaixin Aluminum not only offers custom machining of other types of aluminum products, but we also specialize in finishing aluminum parts.

In the following section, we will explore the factors worth noting about CNC machining including materials, machining tolerances, cutting times and more so you can make an decision.

Tolerance

We have developed a standard set of tolerances that can be CNC machined to ±0.005″ (0.13mm). If you need tighter tolerances, we can provide additional CNC machining services. Simultaneously, you should recognize that aluminum is a very soft metal that is difficult to cut accurately. To minimize unnecessary costly losses, please provide Kaixin Aluminum with 2D drawings in advance.

Material

Kaixin Aluminum uses pre-extruded aluminum heatsinks for CNC machining. Our materials are made of aluminum 6005, 6001-T651, 6061-T651 and 7075-T65.

The 60 series can be deeply machined, welded and plated while the 70 series is tough and suitable for spacecraft and large machinery.

Surface Treatment

Anodizing

Mainly use Type II oxidation featuring the thicknesses of film between 0.0002 and 0.00040 inches (0.005-0.102 mm).

Using anodizing can generate different colors which are subject to electrolytes. The most common colors are black, bronze and red.

Sand Blasting

We can sandblast the surface of the product as the customer needs to keep the product beautiful and well-decorated.

Meanwhile, We have many materials for blasting such as copper ore, quartz sand, emery, and iron sand from which you can choose.

Powder Coating

Featuring a dry coating process, It is electrostatically charged and sprayed onto the surface of the aluminum, and then the powder is cured under heat, which can provide strong corrosion resistance equivalent to the anodizing process for parts.

Kaixin has a wide selection of coating colors. So if you are unsure which one to choose, please contact us for details.

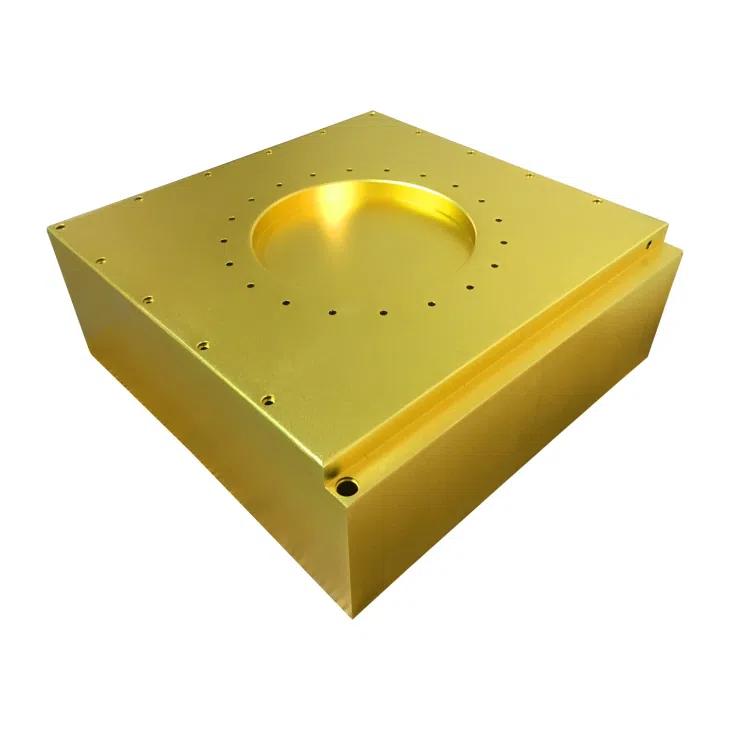

Electroplating

To improve the appearance or function of a part, electroplating is often used in conjunction with other surface treatments, such as anodizing. We can coat aluminum alloys with a variety of metals, including gold, silver, nickel and copper to keep aesthetic and a good touch.

Powder Coating

Anodize

How to Get Your Final CNC Machining Products

in 4 Simple Steps

Providing a CAD Drawing

Before processing, Please submit your 3D or CAD drawings. kaixin will quote you within 24 hours.

Quote and Design

You will receive a quote shortly, after which you will be provided with a feasible design proposal

Order Confirmation

Once you place an order, we will start the CNC machining process immediately.

Shippment

After the CNC processing, final products will be delivered straight to your address after inspection

What types of CNC Machining parts we offer

Well equipped with CNC machines, digital drilling, PYB series CNC Profile Machining Center, milling machines, punching machine, High-frequency welding machine, Hydraulic automatic pipe bending machine etc.Kaixin Enterprise Limited has a strong ability to produce various kinds of CNC precision parts based on your requirement.

As one of China’s professional CNC parts manufacturers and suppliers, we offer the best CNC parts with competitive price. If you’re interested, welcome to contact our factory.

Golden CNC part

Anodizied Aluminum Case

Aluminum battery case

CNC Machining Heatsink

CNC Turning Part

CNC Milling Part

CNC Precision

CNC Precision Aluminum

Applications of CNC Parts

Medical